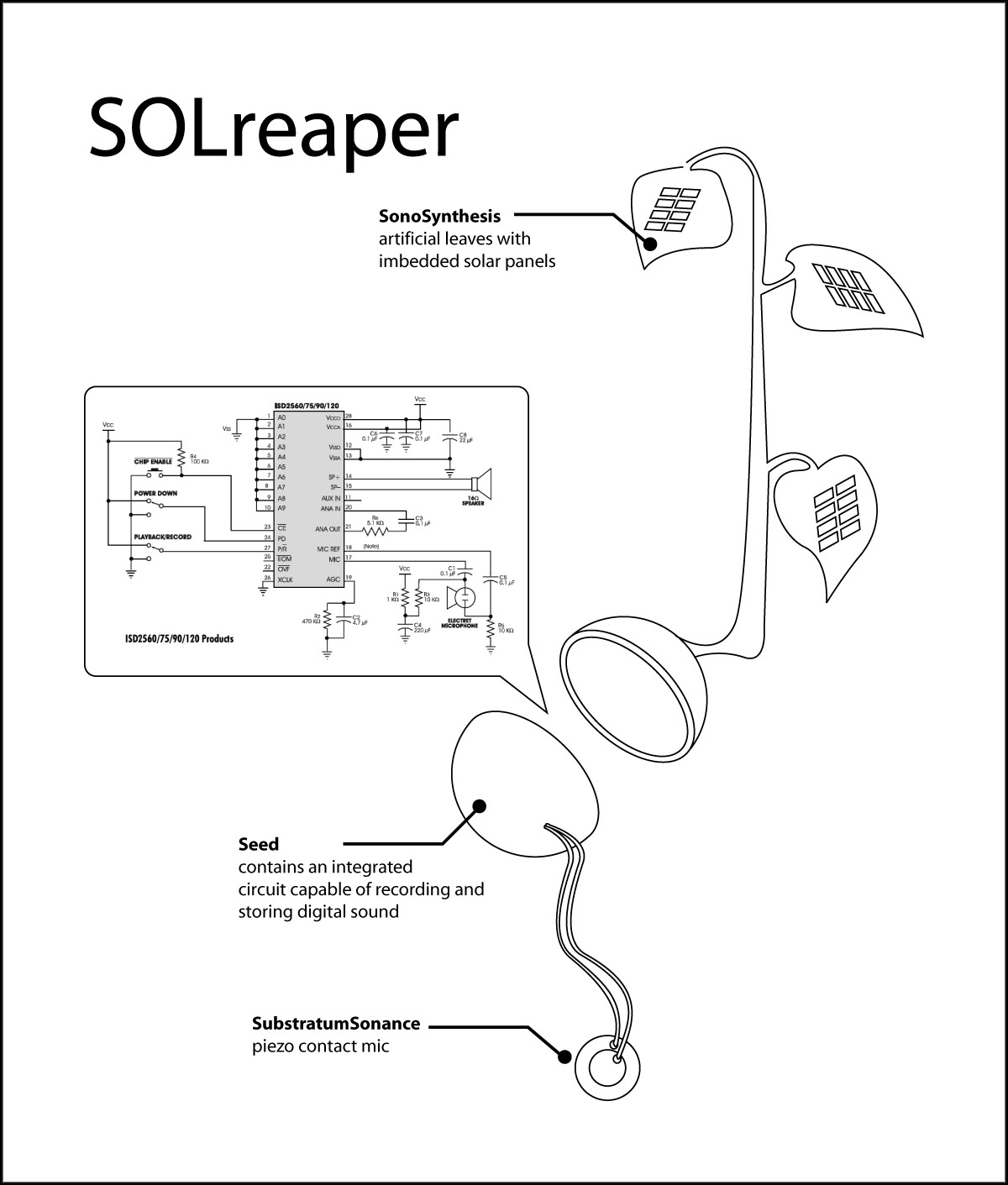

SoundSEEDS are small, green-powered sound devices capable of recording and transmitting sound for use in a live audio performance system. Conceptually, the biological/botanical process of plant, seed, photosynthesis, harvesting, and processing are used as a metaphor for the electronic process.

PROPOSAL

In the true spirit of a WaveFarm, I propose SOUNDseeds - a "green" powered system for gathering sound and data from the environment in order to be harvested and processed through digital sound synthesis.

Genetic Engineering. Several seeds of varying designs will be built to record data from the environment over a period of 2-3 weeks. The seeds will get their energy from either solar or wind power. This natural power will charge a small capacitor, housed inside the SOUNDseed, which in turn will periodically record audio onto a specially designed integrated circuit.

Sowing. Several solar and wind powered recording devices will be planted at various locations throughout the Wave Farm. Over the course of several weeks, these recording devices will gather and store small bits of audio and other data from the environment.

Cultivating. The SOUNDseeds will be self-contained devices, and not require any maintenance during their growth cycle (no need to water or weed).

Harvesting. After a designated period of time (between 2-3 weeks), the SOUNDseeds will be collected and their sounds transferred into a software application designed to analyze and re-synthesize the sounds.

Feasting. Once the sounds have been collected and loaded into the SOUNDseed software application, the sound will be processed - sliced, minced, boiled, fried, steamed and grilled. The software would be a customized granular synthesis program written in Max/MSP. The feast could be any form of live public presentation of the work.

TECHNICAL DETAILS

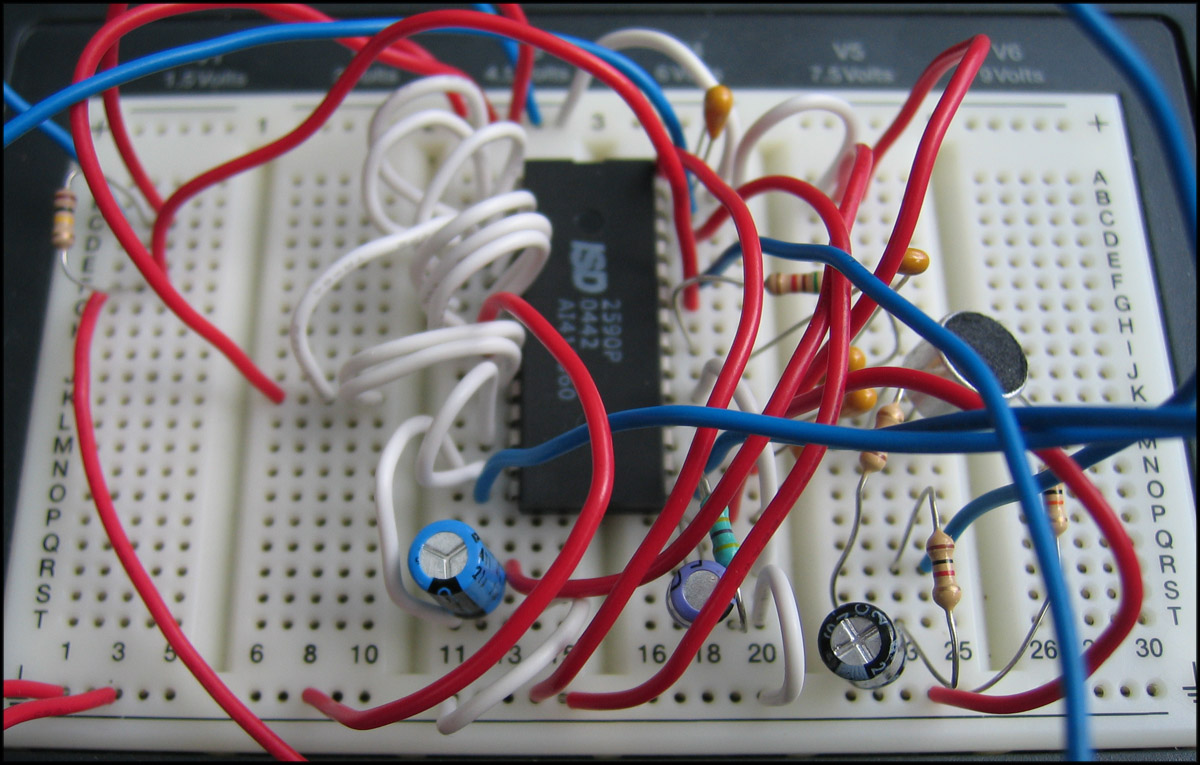

The Seed. The basis for the recording/playback device is the Windbond ISD 2500 Chipcorder( - a small, low-power integrated circuit capable of recording and storing a maximum of 120 seconds of audio. The unit only requires 5V @ 25 mA for operation, making it ideal for solar applications. The major drawback in using this chip is the limited sampling rate (4 - 8 kHz) and recording duration (60 - 120 seconds). Part of this residency will be to research the possibility of using a PIC chip to record and playback high resolution audio and store the data to flash memory in the MP3 format - thereby achieving higher quality audio at longer durations. At the time of this documentation, I have not been able to locate an inexpensive, low-power, commercially available solution: however, a well-versed chip programmer or electrical engineer would easily be able to develop this chip. The Windbond ISD 2500, in many ways an impractical solution, was used for its ease of use and to facilitate research with solar cells.

The Processing/Feasting. Once the sounds have been recorded, they will be transferred onto a computer containing granular synthesis software written in the Max/MSP language. Another reason the final implementation of this piece should be done with PIC and flash memory is the ISD2500 chip doesn't allow for digital transfer of files, therefore the sound will need to be converted back to analog for transfer.

Specially designed granular synthesis software will be written for performance of this piece and customized for each performer. Granular synthesis was chosen for its metaphorical relationship to botany and conversion of seed grain into processed food, and for its sonic textural flexibility. The SOUNDseed Granulator patch, was adapted from a granular synthesis patch written by Les Stuck (original patch is included in the Max/MSP software examples folder).

RESEARCH

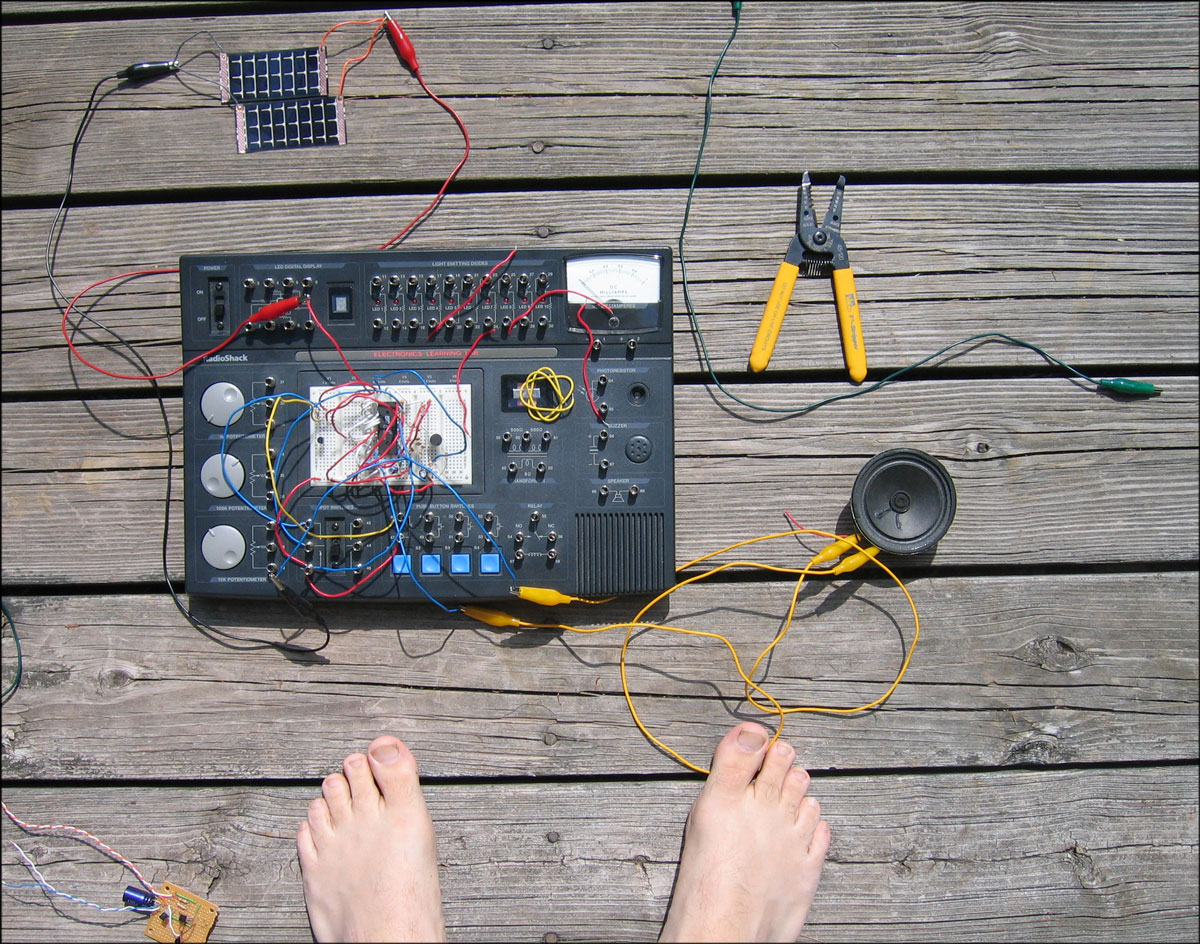

The ISD2500 Chip has been setup to run in "push-button mode" (see ISD2500.pdf for more info), allowing for continuous recording until the chip is full. The chip can be configured to work with either a condensor microphone or piezo disk (contact microphone). Two thin film solar cells, produced by Power Film(, were used as the power source - primarily for their durability and physical flexibility. Two 4.2 V 22 mA cells were wired in parallel, with an average of 5V 40mA in full sunlight.

Continual variations in the amount of sunlight falling on the cells proved difficult for managing the power requirements for making a recording. In Push Button Mode, the Chip Enable (CE) and Power Down (PD) features require the chip to physically be switched on/off. Specifically, the CE needs to be taken "low" to enable the playback and record operations - record addressing is activated by the falling edge of CE. Similarly the PD should be pulled "high" (standby mode) when there isn't adequate power (sunlight) to operate the recording. In order to activate the switch, a CMOS 1381 (commonly used in BEAM circuits) was used to switch on/off when the solar cells produced a voltage greater than the trip voltage (either 3V or 4.6V depending upon the rating of the 1381).

A majority of the residency was spent developing this circuit for stable performance in outdoor application. Once the controls and power supply was completed for the chip; the components were then encased in a waterproof unit and covered using liquid latex - used commonly in mask making applications. First, a clay sculpture of a leaf was made - large enough to facilitate the inclusion of a solar cell and wiring. Then a plaster cast was made of the clay leaf. Once the plaster was dry, the liquid latex was poured halfway into the mold. The solar cell and wiring was then added to the mold, after which, the latex was poured into the remaining half of the mold - thereby encasing the solar cell in the latex leaf. After the latex leaf had dried, the latex covering the solar cell needed to be removed in order for the cell to be exposed to sunlight.

The contact microphone was also covered in latex so as to protect it from the elements as well as allowing it to be submerged in water and allowing the unit to record underwater sounds.

Considering the complications of setting up the installations and having to download the sounds from the unit, I experimented with using a small FM transmitter - a better solution and in line with the concept of transmission arts. The transmitter would send the sound from the surrounding environment to a receiver, which would then be processed using live software. A possible strategy would be to set up small transmitters around the Wavefarm at varying locations. For instance, a piezo disk on a spider web, a small microphone near a birds nest, or a ultrasonic microphone near the ponds which could pick up the sounds of the many bats at Wavefarm as they hunt mosquitoes at dusk.

The summer of 2006 was one of the rainiest on record since at least 19712, and the conditions in Acra during the week of Aug 22-27 reflected that fact. The first three days of the residency the weather was perfect, allowing plenty of time for testing the solar panels. However, the remainder of the residency was very cold and rainy - at one point requiring me to start a fire in the cabin's stove in order to stay warm. Needless to say there was no time to do a final installation of the solar cells.

The rainy weather forced me to switch gears from developing the ISD chip and solar cells. I began testing two wind turbine units that I had purchased from www.windstuffnow.com. The first turbine I experimented with was the Minigen - a small, high voltage/low amp turbine. In 15-20 mph wind this unit can provide 150V @ 25mA. By rewinding the coil with larger gauge wire, you can increase the amperage. Similarly, the more wire you rewind the coil with, the more voltage it will produce. Due to the lack of any substantial wind during my residency, the Minigen was not fully tested. Also, in order for the unit to operate safely in high winds, it needed to be constructed with a furling system. When the unit encounters winds too strong for it to be stable the blades will fold (furl) to an angle that is not perpendicular to the tail. The drag caused by the furling will slow the rotation of the blades. The furling system required machining equipment not available at Wavefarm.

The second wind turbine I built while at Wavefarm was a three-phase vertical axis wind turbine. This came as a fairly basic kit, and was completed during my residency - though there wasn't enough wind to do a sufficient test. Considering the sporadic occurrence of stable wind, it wasn't practical to use wind power for this project without the addition of a battery, which I was hoping to avoid for this project. However, while doing my residency I drew up plans to use LEDs on a blade of the turbine to create a POV light sculpture powered by the turbine (currently a work-in-progress).

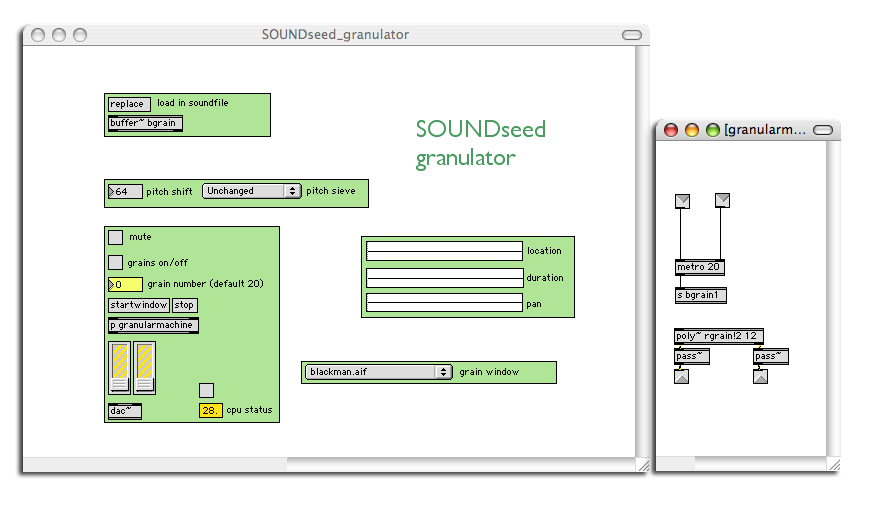

SOUNDseed GRANULATOR

The "SOUNDseed Granulator" is a Max/MSP patch written specifically for this project. It is an adaptation of a granular synthesis process originally written in Max/MSP by Les Stuck. This adaptation includes the conversion of the rgrain object into a poly~ object and a pitch sieve for each grain allowing the synthesis to be tuned (or detuned as the case may be).

The poly~ object is included in the Max/MSP software bundle and allows the programmer greater control for managing the DSP and routing commands to multiple copies (called voices) of the subprogram included in the poly~ object. The use of poly~ in place of rgrain is therefore more flexible and efficient than the original written by Les Stuck.

Sounds collected from the ISD2500 chip are uploaded to a computer running the SOUNDseed Granulator. These sound files are loaded into a buffer which is then read by each poly~ object. An interface allows the user to set range values for the location within the soundfile to be sampled, the duration that each grain is played, and the panning (speaker output) of each sound. The pitch of each grain can be controlled in two ways. The pitch can be adjusted before it is input into the system (global) and/or it can set be pitch shifted individually within each grain - thereby tuned.

Two recordings were made at Wavefarm using the ISD2500 chip and are included with this report. The files are located in the "sounds" folder and are named ISD_sound1.wav and ISD_sound2.wav. These two sounds were also loaded into the SOUNDseed Granulator and the file SOUNDseeds_recording.wav is a compilation of synthesis made with the software.

PERFORMANCE

During my residency, I arranged for Pauline Oliveros to visit Wavefarm with the intention of arranging a performance of Tintinnabulate at Wavefarm later in the year. Together with Tom Roe and Galen Joseph-Hunter of Wavefarm, I organized a special performance of Tintinnabulate for October 19, 2006. The performance was broadcast live on Free103point9 as well as being steamed online. Photos and a recording of the event are included with this report.

Tintinnabulate is a mixed ensemble founded and directed by Pauline Oliveros of Rensselaer Polytechnic Institute in the fall of 2005. The mixed instrumental ensemble consists of graduate students and faculty. The members performing at Wavefarm on October 19 were Alex Chechile, electric guitar/laptop; C. Ryder Cooley, accordion/musical saw/performance art; Bart Woodstrup, laptop; Daniel Valente, violin; Jeff Pitcher, guitar; Michael Bullock, bass/electronics; and Pauline Oliveros, accordion.

Tintinnabulate has performed at RPI, Eyebeam in New York City, The Children's Museum Rensselaer Technology Park in the dome, and telepresence performances with Brown University, Arizona State University and Stanford University.

1 Mouawad, Jad, "Settlement Is Reached With Enron." New York Times Date: July 16, 2005, Date of Access: October 26, 2006

2 Hill, Michael, "Summer Rain Record-Setting for N.Y." Associated Press Date: October 21, 2006 Date of Access: October 26, 2006